winch motor 12v

wolong electric

wolong electric

wolong electric

iron 883 engine

30 kw generator

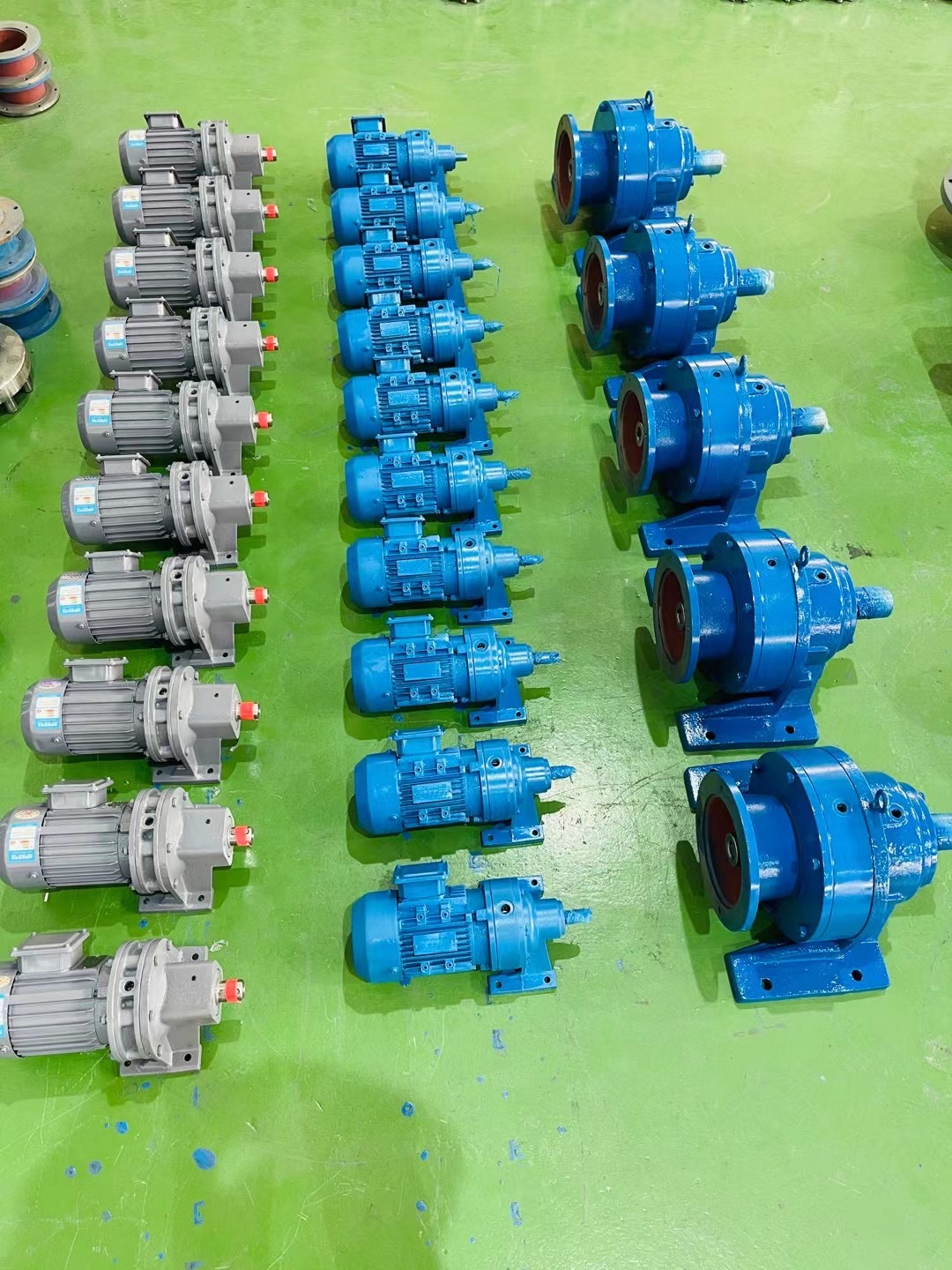

Customized cyclo? drive for servo motors BWD15-11-Y1.5

Model of cycloid reducer

1) B series cycloid reducer BW foot plate type horizontal double-axis cycloidal reducer Reducer BLY flange type vertical mounting special motor direct-connected cycloidal pinwheel reducer BWD foot plate type horizontal mounting ordinary motor direct-connected cycloidal pinwheel reducer BLD flange type vertical mounting ordinary motor direct-connected cycloidal pinwheel Reducer 2) X series cycloid reducer XW foot plate type horizontal double-axis cycloid reducer XL flange type vertical double-axis cycloid reducer XWD foot plate type horizontal ordinary motor direct connection Linear pinwheel reducerXLD flange type vertical mounting ordinary motor direct-connected cycloid pinwheel reducerXWD foot plate type horizontal mounting ordinary motor direct-connected cycloidal pinwheel reducerXLY flange type vertical mounting special motor direct-coupled pendulum Cycloid reducer 3) 8000 series planetary cycloid reducer8000 series XW, XWD type cycloid reducer8000 series XL, XLD type cycloid reducer8000 series XWE, XWED type cycloid reducer Reducer 8000 series XLE, XLED type cycloid reducer 4) F8000 series planetary cycloid reducer FWD, FLD, FL, FW, FWED, FLED, FWE, FLE 5) Z series planetary cycloid reducer Machine JB/T2982-1994 ZW, ZWD, ZL, ZLD, ZWE, ZWED, ZLE, ZLED, ZWS, ZWSD, ZLS, ZLSD 6) 9000 series planetary cycloid reducer 9000 series XW, XWD type cycloid Reducer 9000 series XL, XLD type cycloid reducer 9000 series XWE, XWED type cycloid reducer 9000 series XLE, XLED type cycloid reducer It is the same, but the models launched by each cycloid reducer manufacturer, and the identification method is different) 7) Taiwan Chuanshi 600 series cycloid reducer

Product features and technical specifications of X/B series cycloidal pinwheel reducer X/B series cycloidal pinwheel reducer is a deceleration mechanism with advanced design and novel structure. . In most cases, this reducer has replaced the two- and three-stage common cylindrical gear reducer and cylindrical worm reducer, and has been widely used in military industry, aerospace, metallurgy, mining, petroleum, chemical, marine, light work, food,

XL flange type vertical installation double shaft cycloidal pinwheel reducerXWD foot plate type horizontal installation ordinary motor direct-connected cycloidal pinwheel reducerXLD flange type vertical installation ordinary motor direct-connected cycloidal pinwheel reducerXWD foot plate type Horizontal Ordinary Motor Direct-coupled Cycloid ReducerXLY Flange Vertical Mounted Special Motor Direct-Link Cycloid Reducer3) 8000 Series Planetary Cycloid Reducer8000 Series XW, XWD Cycloid Wheel reducer 8000 series XL, XLD type cycloid reducer8000 series XWE, XWED type cycloid reducer8000 series XLE, XLED type cycloid reducer 4) F8000 series planetary cycloid reducer FWD, FLD, FL, FW, FWED, FLED, FWE, FLE 5) Z series planetary cycloid reducer JB/T2982-1994 ZW, ZWD, ZL, ZLD, ZWE, ZWED, ZLE, ZLED, ZWS, ZWSD , ZLS, ZLSD 6) 9000 series planetary cycloid reducer 9000 series XW, XWD type cycloid reducer 9000 series XL, XLD type cycloid reducer 9000 series XWE, XWED type cycloid reducer Machine 9000 series XLE, XLED type cycloid reducer Note: The essence of the above types of reducers is the same, but the models launched by each cycloid reducer manufacturer have different identification methods. 7) Taiwan Chuanshi 600 Series Cycloid Reducer THM, THHM, THHHM Cycloid Reducer Usage Instructions Precautions

3. Use Haoken technology to improve processing efficiency;

4. The microhardness of Haoke can increase by about 20% after processing;

5. Haoken technology can realize the grain refinement of the processing part, and the wear resistance and corrosion resistance can be improved by more than 50%;

Strictly speaking, it is not possible to replace honing oil with emulsion oil and kerosene.

Large reduction ratio and high efficiency: the speed ratio of single machine reduction can reach 1:87. If multi-stage reduction ratio is adopted, the reduction ratio is larger and the efficiency is above 90%. Smooth operation and low noise: The cycloid needle has a large number of meshing teeth, a large overlap coefficient and the principle of mechanical balance, which limits vibration and noise to a minimum. Reliable use and long service life: Because the main parts are high-carbon Ming steel quenched (HRC58-62), and the running contact adopts rolling friction, basically no wear, so it is durable. Compact structure and small size: due to the use of planetary transmission , the input shaft and the output shaft are on the same axis, so that the size of the model is as small as possible. Reasonable design, convenient maintenance, easy disassembly and installation, minimum number of parts and simple lubrication make the cycloid reducer deeply trusted by users. The first gear ratios are 11/17/23/29/35/43/59/71/87. Secondary ratios are 121/187/289/391/473/595/731/841/1003/1225/1505/1849/2065/2537/3481/5133. The three-speed ratio has 2055-446571 First: Overview of vertical reducer: Vertical cycloidal pinwheel reducer, also known as flange-mounted cycloidal pinwheel reducer, is defined and named according to the installation form of the reducer. This reducer is a kind of planetary transmission principle that has both rotation and The public transmission adopts cycloid needle-tooth meshing to transmit the decelerated power to the output mechanism, so as to meet the requirements of deceleration. It is the deceleration mechanism with the most advanced design and the most novel structure among the four reducer series in the reducer industry. Second: Vertical reducer model: The most fundamental difference in the model representation method of the flange-mounted vertical cycloidal pinwheel reducer produced by our company is that there is a letter L in the model representation to define the meaning of using the first letter L of the Chinese Pinyin alphabet. (the first letter at the beginning of the pinyin of the Chinese character "Li") to indicate. According to the structure of the reducer, the vertical cycloid reducer has the following model representation methods: BLD XLD BLY XLY BLED XLED BLEY XLEY BLSD XLSD BL XL BLE XLE and other series models. Third: the application field and scope of vertical reducer:

Lifting machinery, transportation machinery, mining machinery, metallurgical machinery, petrochemical machinery, textile machinery, printing and dyeing machinery, light industrial machinery, food machinery, pharmaceutical machinery, rubber machinery, plastic machinery, packaging machinery, beer machinery, road construction machinery, environmental protection machinery , Grain and Oil Machinery, etc. various deceleration devices and equipment.

Fourth: Vertical reducer structure:

The entire transmission structure of the vertical cycloid reducer can be divided into three parts: input part, deceleration part, and output part. The input structure is the high-speed part, which is connected to the input motor (motor); the output part is the low-speed part of the reducer. , and its output shaft is connected to the equipment that the user needs to drive through sprockets or couplings, connecting plates, etc.

Fifth: the principle of vertical deceleration:

A double eccentric sleeve with a dislocation of 180° is installed on the input shaft, and two roller bearings are installed on the eccentric sleeve to form an H mechanism. The center hole of the two cycloidal wheels is the raceway of the arm bearing on the eccentric sleeve, and The cycloidal gear is meshed with a group of annularly arranged needle gears on the needle gear to form a small tooth difference internal meshing deceleration mechanism (in order to reduce friction, in the reducer with a small speed ratio, the needle teeth are equipped with needle gear sleeves ).

Sixth: vertical reducer features:

1. Large transmission ratio: the transmission ratio is 1/6~1/87 in one-stage deceleration, and 1/99~1/7569 in two-stage deceleration. More stages can be combined as needed.

2. The transmission efficiency is high. Since the meshing part of the vertical reducer adopts rolling meshing, the average efficiency can reach more than 90%.

3 Small size and light weight: Because not only the principle of planetary transmission is adopted, the input shaft and output shaft are on the same axis, but also has the unique feature of being directly connected with the motor, so the vertical reducer has a compact structure, small volume, Lightweight features.

Seventh: Precautions when using vertical reducer:

(1) This machine is suitable for continuous duty, running forward and reverse. Ambient temperature -10℃~40℃

(2) When the output shaft and input are matched with other parts, direct hammering is not allowed to prevent damage

(3) The keys on the shaft extension of the output shaft and the input shaft are selected according to the size of the ordinary flat key (GB1096-79). The fit tolerance value of the diameter D4 of the frame at the output end of the vertical reducer conforms to the requirements of the tolerance fit (GB1801-79) h9

(4) When using the coupling to connect with the working machine or motor, the axis should be concentric, and the installation error of the vertical reducer should not be greater than the allowable error value of the coupling used.

(5) The reducer can be rotated flexibly by hand after installation

| Model Series | Inline |

|---|---|

| Gear Type | Cycloidal Gear |

| Gearbox Ratio | 11 |

| Low Speed Side | Solid shaft with parallel key |

| Mounting Position | Foot Mount |

| Motor Power (KW) | 1.5 KW |

| Number of Poles | 4 |

| Voltage Class | Low Voltage < 690V |

| Rated Frequency | 50 - 60 hz |

| Motor Rotor Type | 3-Phase squirrel cage motor |

| Electric Motor Enclosure | TEFC |

| IP Rating | IP55 |

| Insulation Class | F |

| Electric Motor Frame | IEC |

| Application Cases | OTR Tire etc. |

| Datasheet Drawing | Click to download the drawing of BWD15-1.5KW |

| PDF Download | GUOMAO cycloidal Reducer pdf |

| Brand | Sogears |

| Country of Manufacture | China |