winch motor 12v

wolong electric

wolong electric

wolong electric

iron 883 engine

30 kw generator

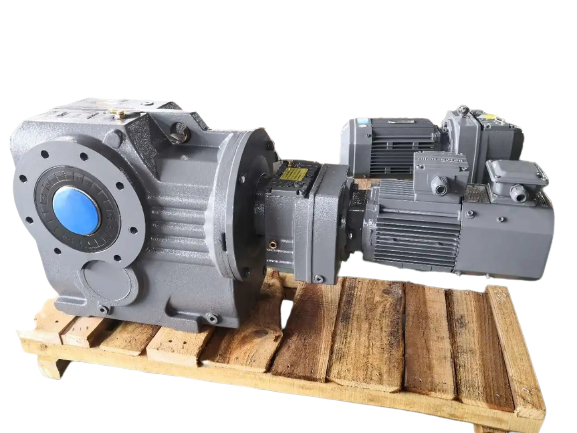

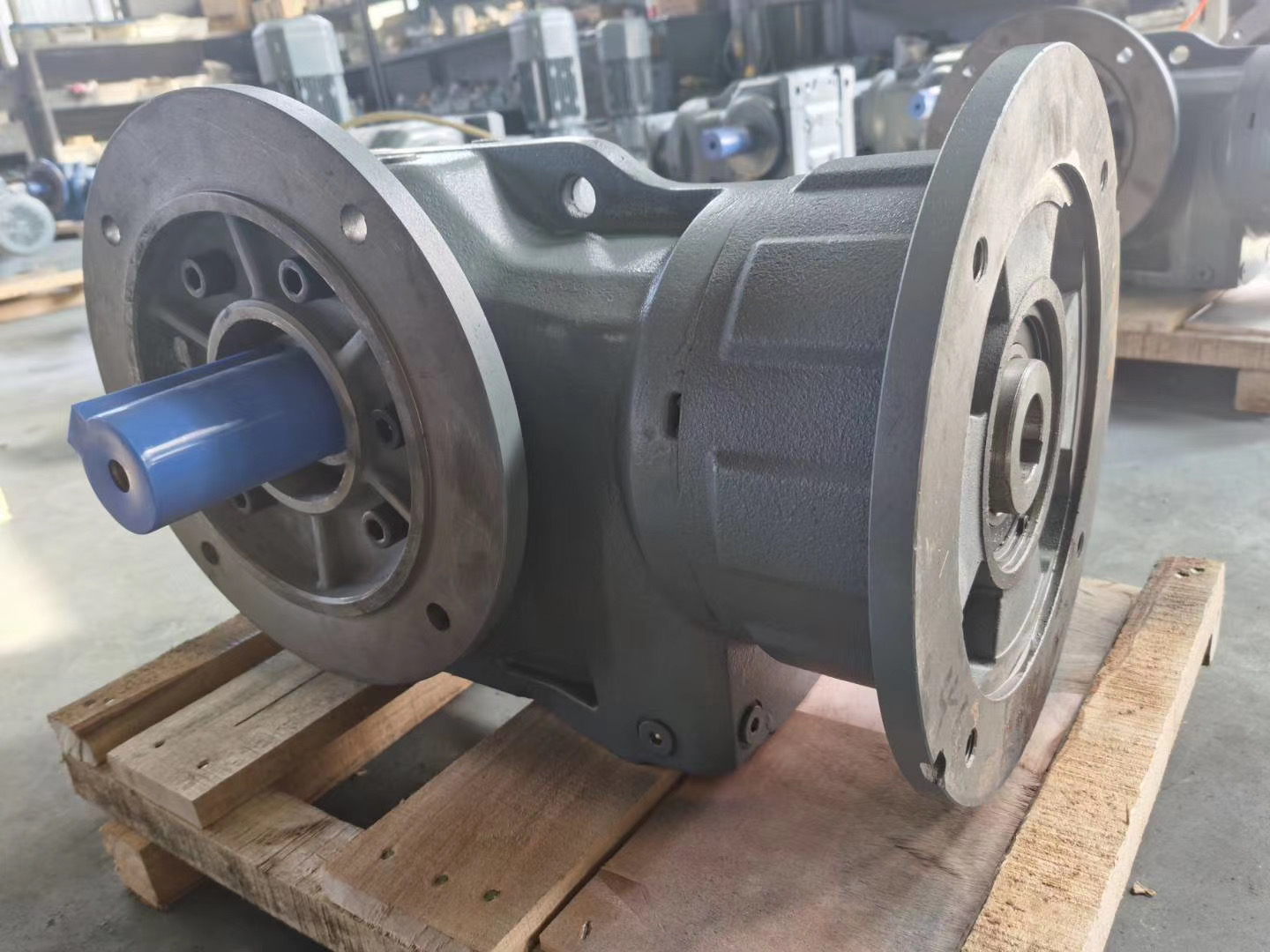

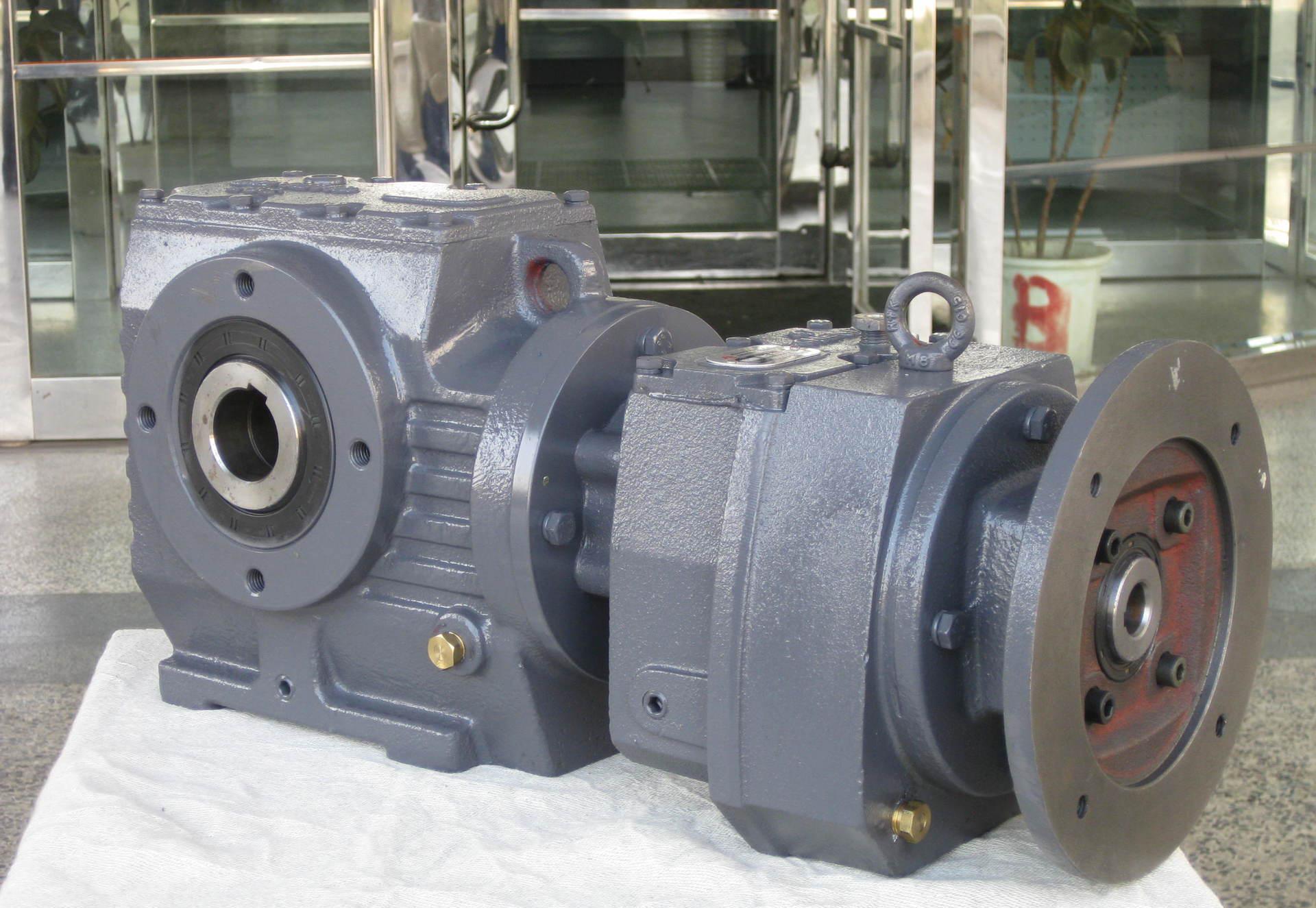

Electric motor and gearbox combination GKH187R107-Y22-4P-167-M5-180°

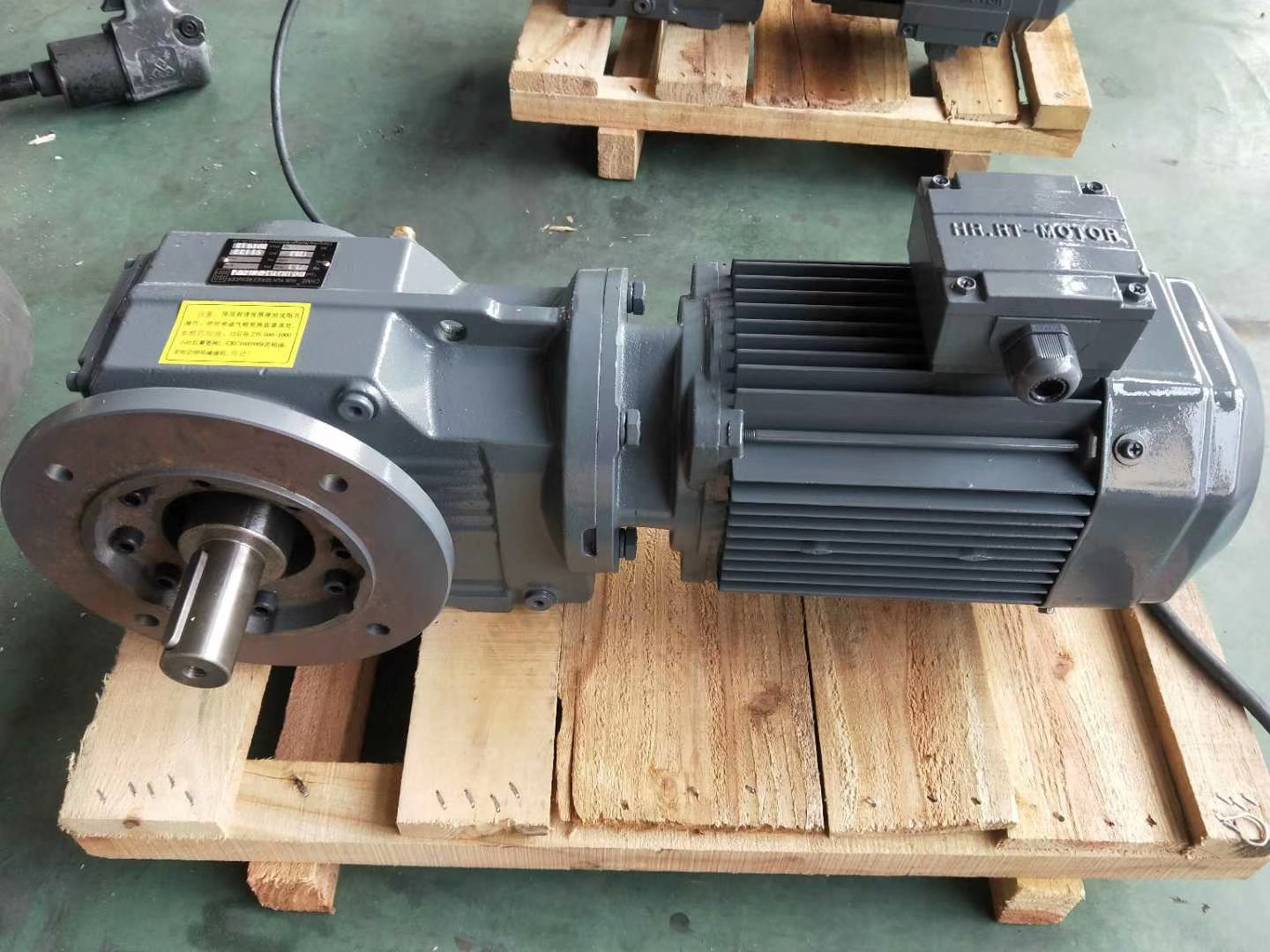

K series helical gear-bevel gear reducer motor, manufactured in accordance with international technical requirements,

has high technology content, saves space, is reliable and durable, has high overload capacity, power can reach 200KW, low energy consumption,

superior performance, and reducer efficiency as high as More than 95%, low vibration, low noise, high energy saving,

Performance characteristics: K series reducer has high technological content, k series spiral bevel gear reducer saves space, is reliable and durable, and has high overload capacity. K series reducer has low energy consumption and superior performance. Spiral bevel gear reducer has low vibration, Low noise and high energy saving.

After-sales service: According to user needs and working conditions, the industry gear reducer is customized, involved in different industries, and makes reasonable application solutions for customers in different industries. Long-term effective service support, can provide k series reducer dimension drawings and CAD drawings. K foot mounted bevel gear-helical gear reducer KA..B foot hollow shaft mounted bevel-helical gear reducer KV..B foot spline hollow shaft (DIN5480) installation of bevel-helical gear reducer KH..B Foot Hollow Shaft Shrink Disc Mounting Bevel-Helical Gear Reducer KFB5 flange mounted bevel-helical reducer KAFB5 flanged hollow shaft mounted bevel-helical reducer KVFB5 flange spline hollow shaft (DIN5480) installation of bevel-helical reducer KA hollow shaft mounted bevel-helical reducer KV spline hollow shaft (DIN5480) installation of bevel-helical reducer KH hollow shaft shrink disk installation bevel-helical reducer KT hollow shaft torque arm installation bevel-helical reducer KAZB14 flanged hollow shaft mounted bevel-helical reducer KVZB14 flange spline hollow shaft (DIN5480) installation bevel-helical reducer KHZB14 flanged hollow shaft shrink disk installation bevel-helical reducer

K-base type solid shaft output

KW-base type flat key hollow shaft output

KZ-base type shrink disk hollow shaft output

KH-base type involute spline hollow shaft output

KF-Flange solid shaft output

KL-Flange type flat key hollow shaft output

KZL-Flange Shrink Disc Hollow Shaft Output

KHL-Flange Involute Spline Hollow Shaft Output

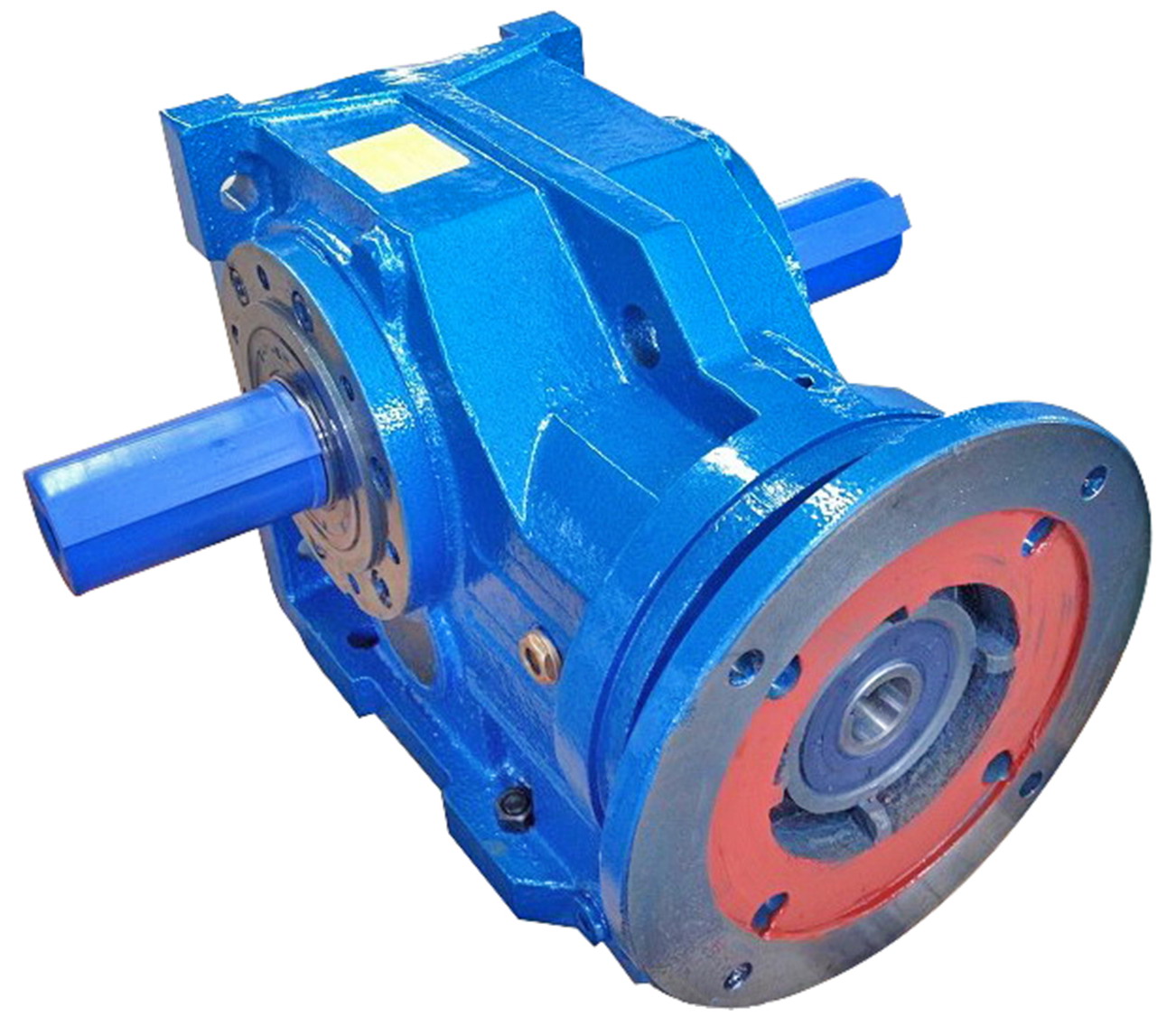

Basic models of k series reducer: K87 reducer, K97 reducer, K107 reducer, K127 reducer, K157 reducer, K167 reducer, K187 reducer

Solid shaft output combination type: K77R37, K87R57, K97R77, K107R77, K127R87, K157R97, K167R97, K187R97, K157R107, K167R107, K187R107

Hollow shaft output combination type: KA77R37, KA87R57, KA97R77, KA107R77, KA127R87, KA157R97, KA167R97, KA187R97, KA157R107, KA167R107,

KA187R107

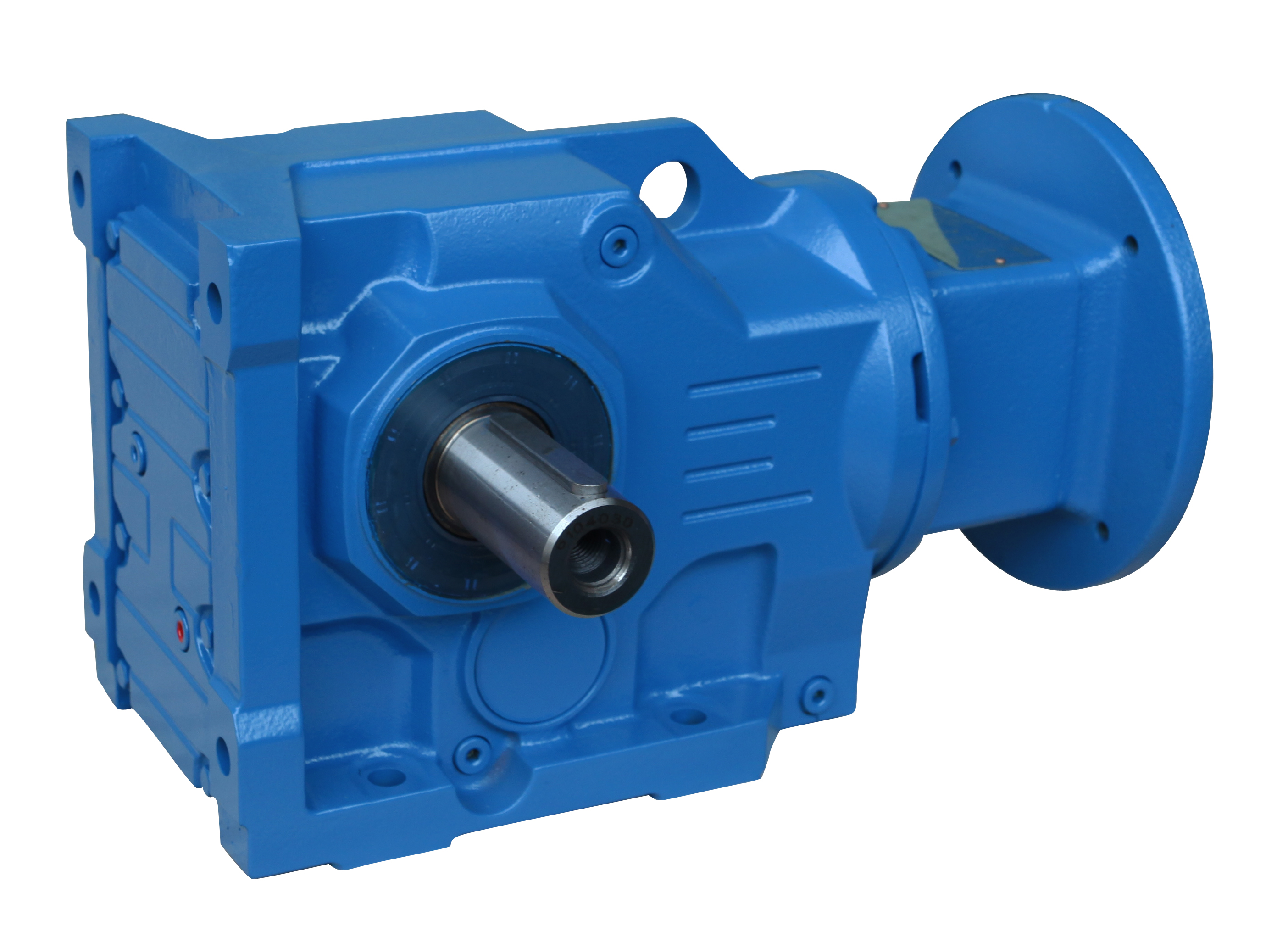

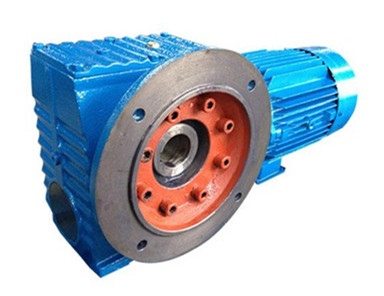

The geared motor is designed on the basis of the modular combination system, and there are many motor combinations, installation positions

and structural schemes.

The modular combination system allows the gear unit to be combined with the following components:

- Combined with a constant field synchronous motor to form a servo gear motor;

- Combined with AC squirrel-cage motor for hazardous environment work;

Combined with DC motor;

The transmission is combined into a stepless speed-regulated deceleration motor.

The reducer with the input shaft without electric motor can be provided, or the reducer with open input end for installation can be provided.

A complete modular combination system provides you with an ideal choice.

Low energy consumption, superior performance, reducer efficiency up to 96%. Low vibration and low noise.

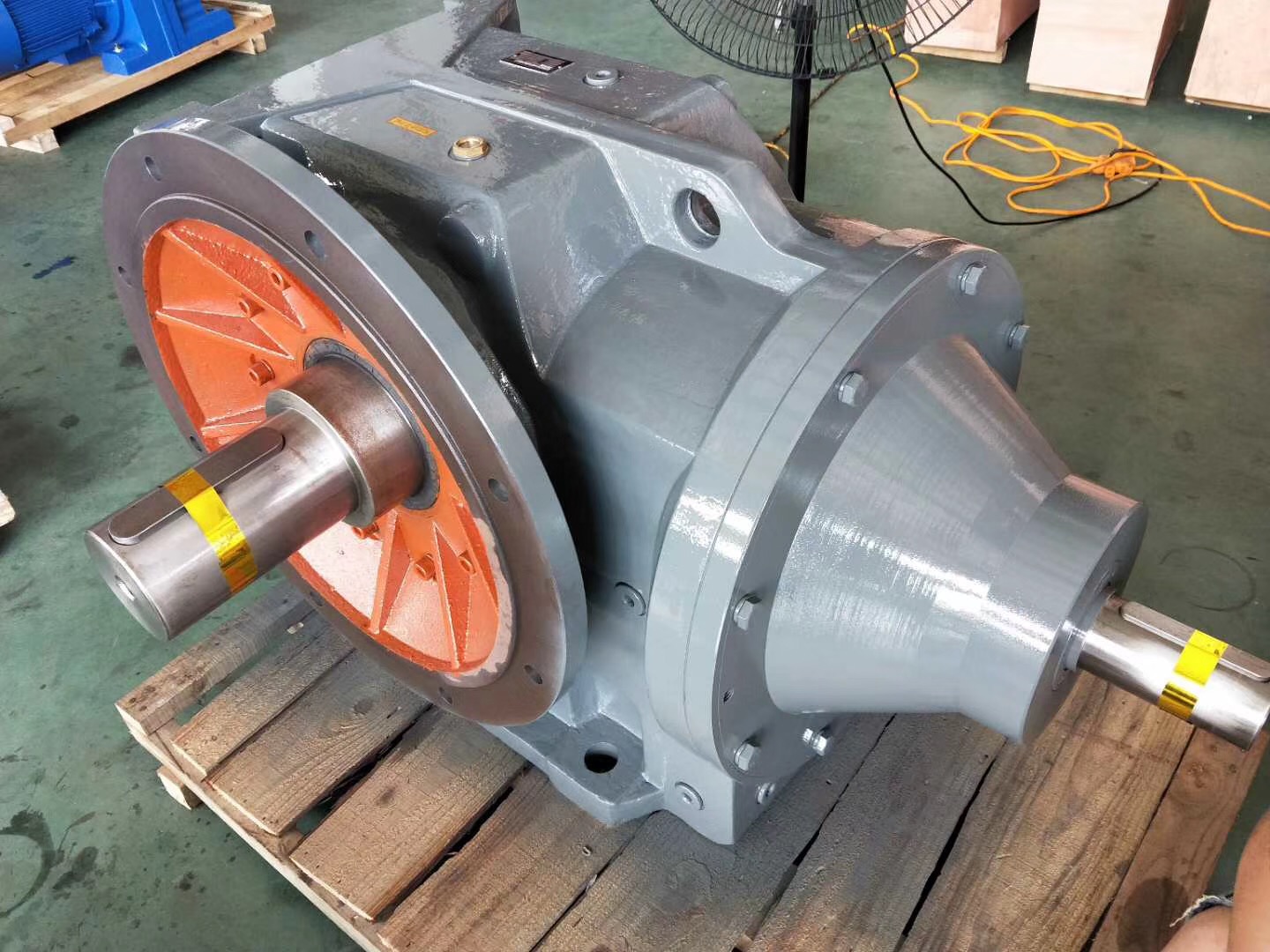

The high-rigidity cast iron box with ribs; the helical gear is made of forged steel, and the surface is carburized and hardened; after processing,

the shaft parallelism and positioning accuracy are ensured,

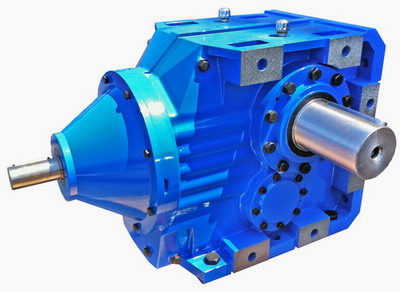

Foot Mounted Helical Gears - Bevel gear reducers have two machined foot mounting flats and are available with either a B5 flange or a B14 flange,

the latter connecting only to the hollow shaft.

Fourth, K series bevel helical gear reducer manufacturers - Yuci Intelligent

K series gear reducer, manufactured in combination with international technical requirements, has a high technological content;

space saving, reliable and durable, high overload capacity, power up to 132KW; low energy consumption, superior performance,

reducer efficiency as high as more than 95%.

K series reducer is a combination of multi-stage helical gears, which has higher efficiency than single-stage worm gear reducer.

The K series reducer is designed on the basis of the modular combination system, there are a lot of motor combinations,

installation positions and structural schemes, with high double torque efficiency and long life gear, with foot installation,

flange installation and shaft installation type.

Non-standard customization of k series reducer motor

1. Focus on the customization of industrial reducers, get involved in different industries,

and make reasonable application solutions for customers in different industries.

| Model Series | Right Angle |

|---|---|

| Gear Type | Helical-bevel Gear |

| Low Speed Side | B5 flange-mounted and hollow shaft with shrink disk |

| Mounting Position | M5 |

| Motor Power (KW) | 22 KW |

| Number of Poles | 4 |

| Voltage Class | Low Voltage < 690V |

| Rated Frequency | 50 - 60 hz |

| Motor Rotor Type | 3-Phase squirrel cage motor |

| Electric Motor Enclosure | TEFC |

| IP Rating | IP55 |

| Insulation Class | F |

| Electric Motor Frame | IEC |

| Datasheet Drawing | Click to download the drawing of KH187R107 |

| PDF Download | Series K helical bevel gearmotor |

| Brand | Sogears |