winch motor 12v

wolong electric

wolong electric

wolong electric

iron 883 engine

30 kw generator

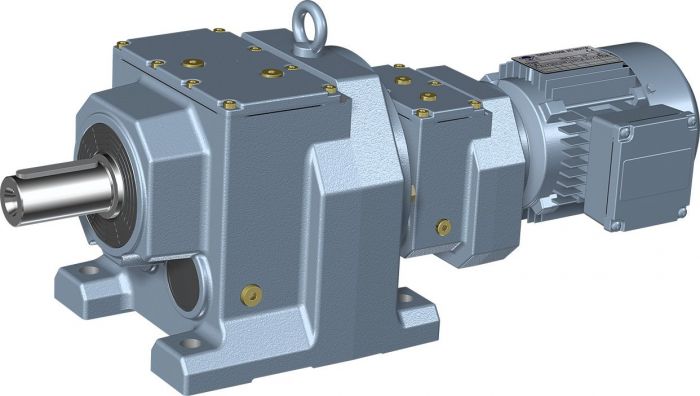

Inline Helical Gearmotors GR57R37-Y0.18-4P-471-M3-270°

Performance characteristics 1. R series gear reducer products have low noise, high energy saving and low vibration; 2. Select high-quality forged steel material, rigid cast iron box, and the surface of the gear undergoes high-frequency heat treatment; 3. After precision machining to ensure shaft parallelism and positioning bearing requirements, the reducer forming the helical gearmotor drive assembly is equipped with various types of motors, which are combined into mechatronics, which fully guarantees the quality characteristics of the product; 4. Manufactured in combination with international technical requirements, with high scientific and technological content; 5. Space saving, reliable and durable, high overload capacity, power up to 160KW; 6. Low energy consumption, superior performance, and the efficiency of the reducer is over 95%; 7. R series can bear higher radial load.

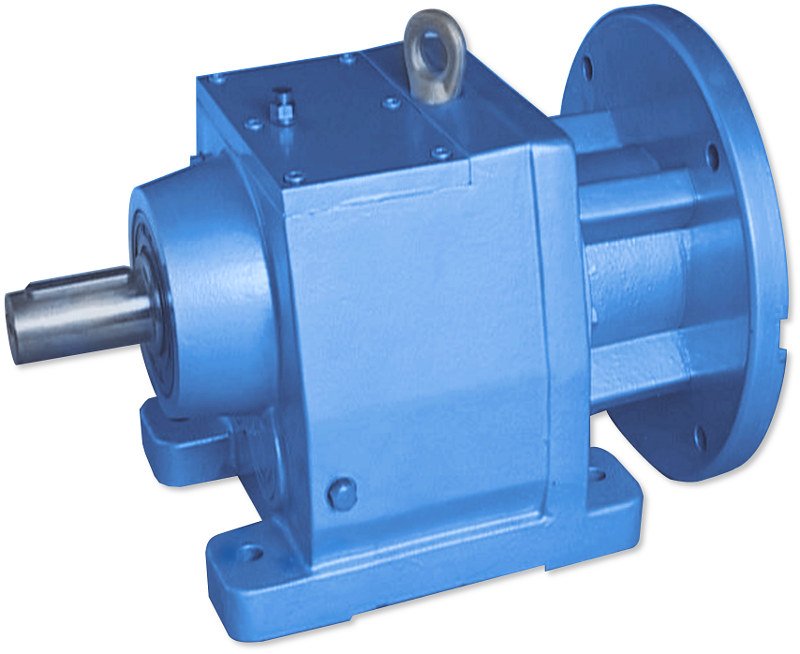

Speed ratio range: R basic type 3.33~289.74, RX type 1.3~8.65, R/R combined type can reach 27001 Torque range: R basic type 85~18000 Nm, RX type 20~1680 Nm Power range: R basic type 0.18 ~ 160 kW, RX type 0.18 ~ 132 kW It can be installed with foot type, flange type and shaft type, with input shaft or direct connection of various motors.

1. The product adopts the design idea of serialization and modularization, and has a wide range of adaptability. This series of products has a lot of motor combinations, installation positions and structural schemes. integration. 2. The R series helical gearmotor hardened reducer is manufactured in combination with international technical requirements and has a high scientific and technological content; 3. The hardened gear reducer saves space, is reliable and durable, has high overload capacity, and has a power of up to 132KW;

4. Low energy consumption, superior performance, and the efficiency of the reducer is as high as 95%; 5. Small vibration, low noise and high energy saving; 6. R series helical gearmotor hard-tooth surface reducer adopts high-quality forged steel material, rigid cast iron box, and the gear surface undergoes high-frequency heat treatment; 7. After precision machining to ensure shaft parallelism and positioning bearing requirements, the reducer forming the helical gearmotor drive assembly is equipped with various types of motors, which are combined into mechatronics, which fully guarantees the quality characteristics of the geared motor products.

R series geared motor/R reducer chooses _ rigid cast iron box, the hardness and impact performance of the box have been greatly improved, helical gearmotor reducer, hard tooth surface reducer adopts serialized and modular design ideas, transmission It has the advantages of fine grading, high transmission efficiency, low energy consumption, high performance and wide adaptability. There are a lot of motor combinations, installation forms and structural schemes, and the transmission ratio is finely graded to meet different working conditions, realize mechatronics, high transmission efficiency, low energy consumption and high performance. The R series geared motor is designed and manufactured on the basis of the modular combination system. There are many motor combinations, installation forms and structural schemes. The transmission ratio is finely graded, which can meet different working conditions, realize mechatronics, high transmission efficiency, and low energy consumption. ,performance_. High-rigidity cast iron box with ribs; hard-toothed surface gears are made of _alloy steel, the surface is carburized and quenched and hardened, and the grinding teeth are finely processed, with stable transmission, low noise and large bearing capacity. Low temperature rise and long life. Wide range of applications, mostly used in metallurgy, sewage treatment, chemical, pharmaceutical and other industries.

Specifications of R series helical gearmotor reducer:

1. R17, R27, R37, R47, R57, R67, R77, R87, R97, R107, R137, R147, R167

2. RF17, RF27, RF37, RF47, RF57, RF67, RF77, RF87, RF97, RF107, RF137, RF147, RF167

3. RX37, RX57, RX67, RX77, RX87, RX97, RX107, RX127, RX157

The R series geared motor has the same technical level in foreign countries. The surface of all transmission gears has undergone high-frequency heat treatment, which greatly enhances the hardness and wear resistance of the gears. R series geared motor chooses _ rigid cast iron box, the hardness and impact performance of the box have been greatly improved, the series and modular design concept is adopted, the transmission ratio is finely graded, the transmission efficiency is high, the energy consumption is low, and the performance _ , has a wide range of adaptability. R series geared motor has a variety of motor combinations, installation positions and structural schemes, and you can choose any speed and various structural forms according to your actual needs.

R series geared motor This series of reducer is designed and manufactured on the basis of the modular combination system. There are a lot of motor combinations, installation forms and structural schemes. , low energy consumption, performance _. High-rigidity cast iron box with ribs; hard-toothed gears are made of _alloy steel, the surface is carburized and quenched and hardened, and the teeth are finely machined, with stable transmission, low noise, large bearing capacity, low temperature rise and long service life.

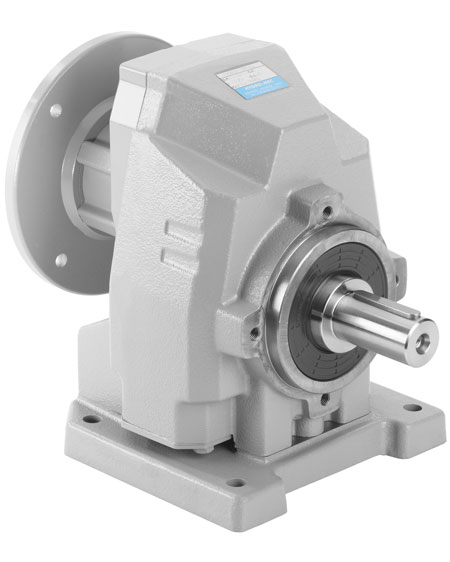

2. Features of R series strong helical gearmotor reducer: ; 1. Small offset output, compact structure, limited use of box space, secondary and tertiary in the same box. ; 2. The integral casting box is adopted, and the box structure has good rigidity, which is easy to improve the strength of the shaft and the life of the bearing. ; 3. Installation method: foot installation and flange installation have large and small flanges, which are easy to choose. 4. For solid shaft output, the average efficiency is 96% for the second stage, 94% for the third stage, and 85% for the RR combination. ; 5. The RM series specially designed for stirring can carry larger axial force and radial force. 3. Scope of application R series geared motor is widely used in light industry, food, beer and beverage, chemical industry, escalator, automatic storage equipment, building materials machinery, iron and steel metallurgy, environmental protection, power plants, coal, mining, papermaking, wood-based panels, Automobile, port (airport, wharf), tobacco machinery and other fields. 4. Technical parameters of R series geared motor; Speed ratio range: R basic type 3.33~289.74, RX type 1.3~8.65, RR combined type can reach 27001; Torque range: R basic type 85~18000 Nm, RX type 20~1680 Nm ; Power range: R basic type 0.18 ~ 160 kW, RX type 0.18 ~ 132 kW; The R series geared motor has a compact structure, and uses the space of the box to the maximum. The second and third stages are in the same box, and the integral casting box is adopted. The rigidity of the box structure is good, and it is easy to improve the strength of the shaft and the life of the bearing.

Strong: Has higher torque ratings than market standards. Silent low noise: unique tooth profile design and tooth surface fine grinding process. Standard Modular: Optimized design of parts and convenient equipment storage for the whole unit. Smart is easy to choose and choose: the selection is diversified, and the assembly and delivery are flexible.

Gear: The helical gearmotor adopts the DIN standard lengthened tooth shape design, the tooth surface adopts the carburizing and quenching heat treatment process, and the imported CNC forming mill is finely ground. Body: Made of GG20 standard pearlite gray cast iron, the internal and external structure are strengthened. Shaft: Made of high-quality alloy steel quenched and tempered, and the matching gear adopts the fine grinding process.

Bearings: Adopt international well-known brands such as SKF, FAG, NSK, etc., to fully meet the occasions where the output shaft and the input shaft end are subjected to large cantilever loads. Oil seal: Adopt imported brands such as NOK and SOG, and can choose double oil seal with dust lip on the outer seal. Lubrication: Gears and bearings are splash lubricated with oil grooves, and output shaft end bearings are lubricated with permanent grease. Efficiency: The efficiency of single-stage gear transmission can reach more than 98%.

1. R series helical gearmotor reducer has small offset output, compact structure, reasonable use of box space, and the second and third stages are in the same box. 2. The R series geared motor adopts an integral casting box, which has good structural rigidity and is easy to improve the strength of the output shaft and the life of the bearing. 3. Installation method of R series helical gearmotor reducer: foot installation, flange installation with large and small flanges, easy to choose. 4. Solid shaft output, the average efficiency is 96% for the second stage, 94% for the third stage, and 85% for the R/R combination.

Structure: Geared motors with FUNO integrated motors up to 45kW (pinion mounted directly on the motor shaft). The universal motor mounting connector (input U-connector) can be used to install standard B5 type IEC motors. Body: The body of size 132 and below is aluminum alloy standard parts, and the body of size 160 and above is standard cast iron body. Protection: IP55, higher protection available on request. Insulation: Use Class F insulation, suitable for working environments with a relative humidity of up to 95%. Energy efficiency grade: FUNO integrated motors all meet the GB18613-2006 standard 3 energy efficiency grade. Type: Assembling motors with special requirements such as braking, frequency conversion, explosion-proof and so on.

When purchasing a reducer, the user can provide the specific operating parameters of the R series helical gearmotor hardened reducer you choose: such as how much motor power is required, how much the transmission ratio is required, or how many revolutions per minute the output speed is required, and the installation form. Use load, etc., to facilitate the company's technical staff to cooperate with your selection!

| Model Series | Inline |

|---|---|

| Gear Type | Helical Gear |

| Gearbox Ratio | 471 |

| Low Speed Side | Solid shaft with parallel key |

| Mounting Position | Foot Mount |

| Motor Power (KW) | 0.18 KW |

| Number of Poles | 4 |

| Voltage Class | 400 V |

| Rated Frequency | 50 - 60 hz |

| Motor Rotor Type | 3-Phase squirrel cage motor |

| Electric Motor Enclosure | TEFC |

| IP Rating | IP55 |

| Insulation Class | F |

| Electric Motor Frame | IEC |

| Application Cases | Veneer gluing machine in Lumber and plastic industry etc. |

| Datasheet Drawing | Drawing Download For R57R37 |

| PDF Download | Series R helical gearmotor |

| Brand | Sogears |